When you buy through links on our site , we may earn an affiliate military commission . Here ’s how it works .

Scientists have devised a new plan of attack to making large , transparent screens at low cost — and they trust it could lead to more affordable transparent TVs in the near future .

Using a unexampled kind of film fabric , scientists have produce a 100 - inch nano transparent concealment ( NTS ) that is as thin as a human hair and capable of demonstrate detailed images with a mellow level of color and low-cal clarity .

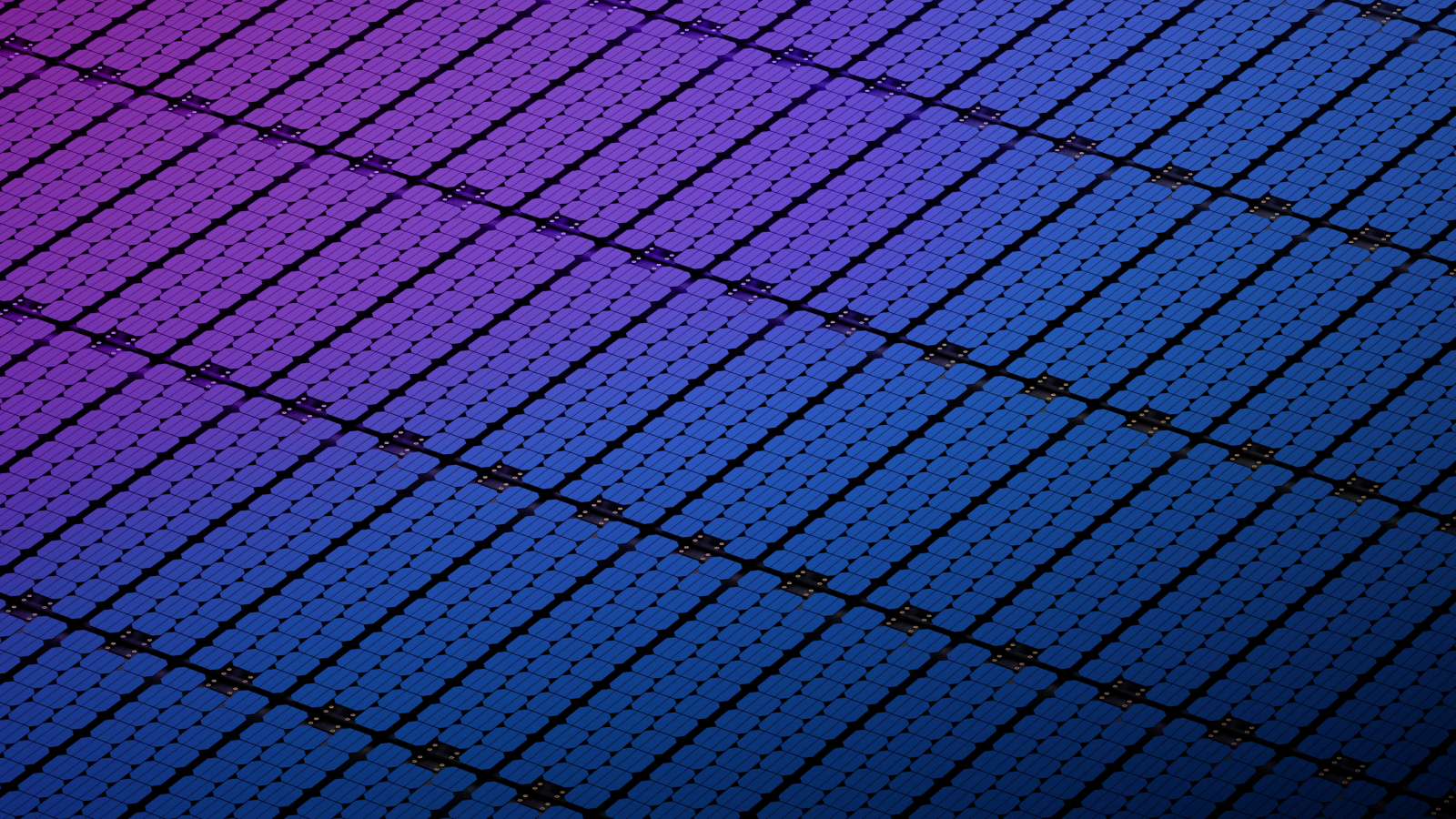

The 100-inch nano transparent screen (NTS) is made in a roll-to-roll process in which a sheet of film is treated with tiny particles of titanium dioxide.

In summation to its calorie-free and conciliatory show , the board ’s transparentness can be adjusted — with the screen capable of showing the most detail when at its most opaque . It is also highly brooding to targeted light , farm clear image when tally with a beam from a potent projector , and has a lossless 170 - level viewing angle on either side .

researcher at the Korea Institute of Machinery and Materials ( KIMM ) , in collaborationism with the individual companionship Meta2People have also started to commercialize the NTS , which is made in a roll - to - roll process in which a sheet of film is treated with tiny particles of titanium dioxide .

These nanoparticles give the NTS its durability and improve the optical quality of the film , the scientist pronounce , intend images project onto it remain exonerated . The film is also layer with a variety of crystal polymer love as a polymer scatter liquid crystal ( PDLC ) picture show . By applying an electrical field to the crystals , the PDLC can be made more or less transparent — allowing the concealment to become more unintelligible when users want to see more detail on the screen .

The 100-inch nano transparent screen (NTS) is as thin as a human hair.

Purchasing established transparent OLED screens would cost KRW 100 million ( approximately $ 72,000 ) , the researchers added . But their newfangled control board would be just one - ten percent of that figure . That ’s because the manufacturing physical process is easy to replicate due to its comparative simplicity , they claimed . It can already be retroflex in existing manufacturing conditions and is highly tolerant to utmost heat and cold — meaning it can be used indoors and outdoors .

— diminutive , transparent splintering could transmute your smartphone into a professional - score television camera

— Computer inspired by Japanese art of paper - film editing has no electronics and stores datum in tiny cubes

— novel invention transforms any smartphone or TV show into a holographic projector

" The technology for manufacturing NTSs is a trend - edge , innovative technology created through the compounding of nanomaterials and nanomanufacturing technology with existing IT technology , " sound out Jun - Ho Jeong , principal researcher at KIMM in astatement . " Going forward , we will focus on research and development to continuously improve the quality of NTSs and lead the popularization of guileless screens . "

The research worker have only start up on their journey to market the NTS screen , but they have patent their technology in collaboration with scientists at Meta2People .